Home > Servo Control Valves

For more information call +44 (0)1726 839 909 or

complete the contact form below and we will contact you

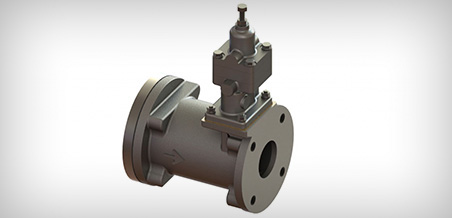

Solenoid Operated

Preventing over filling of tanks, our solenoid operated servo valves provide a controlled closure from a high level alarm without sudden shock that could affect a pump’s operation.

Pressure Regulating

Regulate the pressure of a pipe line without the need for power. We manufacture mechanical pressure regulators to fit to our servo valves for controlling conditions in a line for protection and efficiency.

Check Valves

Check valves are used to prevent the reverse flow of liquids and gases. Designed for military applications, high quality sealing materials with a double sealing system ensures reliable leak protection.

Flow Regulating

The flow regulating pilot uses the servo valve to maintain flow/pressure. It offers switched flow control between two set points and has been successfully installed in fuel and chilled water by-pass.

Related Documents

The AMS Process

We can contact back within 1 working day to:

- Clarify technical information

- Submit a quotation

- Organise a digital meeting to discuss your needs, or

- Arrange for a site visit to view your application

Call now on +44 (0)1726 839 909