The AMS manufactured FLYTE valve, bulk loader/dry break coupling, level switches and level gauges have been approved and manufactured for the rail industry since the 1980’s.

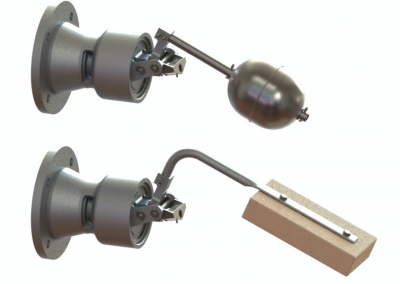

NEW HEAD FOR CONFINED SPACES

To solve a specific problem with access and the lack of height between a fuel tank and the trains body, AMS have modified the head of our approved level sensors to allow fitting in confined spaces.

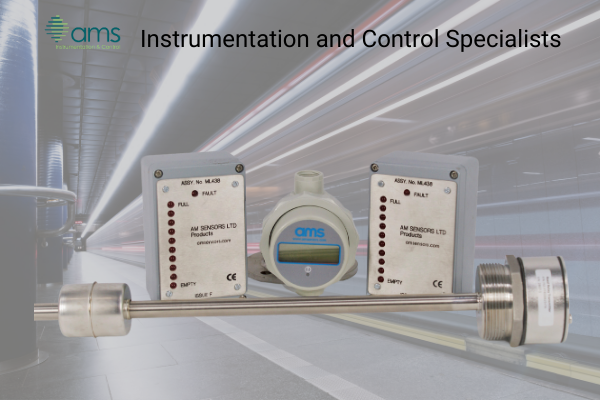

IN HEAD TRANSMITTER REDUCES COSTS

In addition to this, we looked at the whole system for the customer and managed to change the separate transmitter that is traditionally used with other manufacturers parts and fit our in head “puck” style transmitter within the new limited height sensor head.

This development removed the need for the transmitter to be located in a separate box on the side of the tank and allowed the sensor to be wired directly to the indicators, saving significant additional costs in materials and wiring time.

DIGITAL INDICATORS ENHANCE FEATURES

Also completing trials has been the upgrading of traditional and now expensive analogue and LED based indicators that have been used on fuel, water and other fluid tanks. The new lower cost digital indicators have more flexible options, not only saving money but allowing the information gathered to be used for efficiency monitoring and improvement programs.

For further information about our rail products please contact us for help, look at our other #rail blog posts or review or product pages.