Home > Level Measurement > Sight Glass Level Gauge Indicator

For more information call +44 (0)1726 839 909 or

complete the contact form below and we will contact you

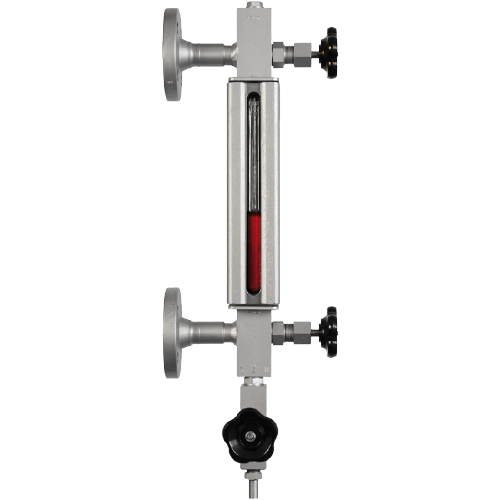

Sight Glass Gauges

Suitable for aggressive applications and widely used on boiler applications with steam, using borosilicate glass they provide a direct indication of the contents level and are often used alongside level transmitters to provide workers around the vessel with an instant visual indication of contents. They can also be used to quickly verify transmitter readings.

The main part of a glass gauge is the body which supports and protects the glass. The body can easily be fitted with valves to allow isolation from the tank and easy removal. Reflex gauges are a version of glass indicators fitted with special optics to allow direct viewing of clear liquids.

- Direct reading of level

- Continuous indication without power

- Suitable for aggressive liquids

- Used widely in chemical industry, petrochemical, oil and gas, shipbuilding, power

- Works well with steam

For more information contact us by email below or call +44(0)1726 839 909.

Quick Links:

> Alarm and control panels

> Digital indicators and controllers

> Fabrications for level applications

> Float switches

> Hydrostatic level transmitters

> Magnetic level gauges and indicators

Related Documents

The AMS Process

We can contact back within 1 working day to:

- Clarify technical information

- Submit a quotation

- Organise a digital meeting to discuss your needs, or

- Arrange for a site visit to view your application

Call now on +44 (0)1726 839 909