Home > Level Measurement > Radar Level Measurement

For more information call +44 (0)1726 839 909 or complete the contact form below and we will contact you

Guided Wave Radar Level Transmitter

Guided Wave Radar, or TDR, is one of the most versatile methods of level measurement giving reliable results in both liquids and solids, even in applications with foam, condensation or vapours.

Supporting a range of guided waver radars, offering both Vega’s range and our own product, helping you choose the one that suits your level measurement needs best. We can also support site preferences or standards for other manufacturers GWR’s, often suppling their radar in a bypass chamber or as part of a complete level control systems.

- Ammonia Storage Tanks

- Fuel Storage

- Interface Measurement

- Powder Silos

- Separators

- Bitumen

- Liquified Gas

For more information contact us by email below or call +44(0)1726 839 909.

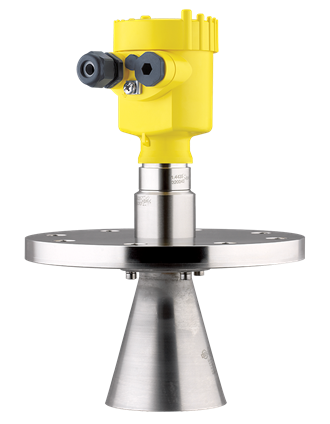

Non-contact Radar Level Transmitter

Non-contact radar provides continuous level measurement by sending a signal from above towards the medium without the sensor coming in to contact with the contents being measured.

Radar calculates the level by measuring the time it takes for a signal that is sent by the sensor to reflect from the medium and be received back by the sensor. This means that the longer it takes to receive the signal back the lower the level. Advancements in radar technology have reduced costs to enable them to be competitive in applications where ultrasonics were previously used.

- Unaffected by pressure and temperature

- Suitable in dust

- Easy to remove

- Used in solids and liquid applications

- Sensors as low as £405.00

- No moving parts – maintenance free

- Suitable for aggressive liquids

Contact us for more information by email below or call +44(0)1726 839 909.

The AMS Process

We can contact back within 1 working day to:

- Clarify technical information

- Submit a quotation

- Organise a digital meeting to discuss your needs, or

- Arrange for a site visit to view your application

Call now on +44 (0)1726 839 909