Home > Instrument Chambers and Bridles

For more information call +44 (0)1726 839 909 or complete the contact form below and we will contact you

Instrument Chambers

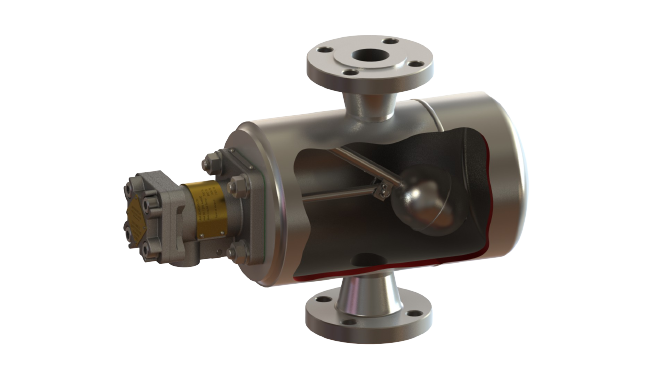

Also known as bypass chambers, these fabricated vessels mount on the side of storage vessels to allow an instrument to be isolated from the tank for maintenance or replacement. We can supply individually or as an assembly.

AMS range of vertical and horizontal chambers are fabricated to suit various types of level measurement technology.

Sold with our own level technology, we also fabricate to suit other manufacturers instrumentation, often being able to supply the package cheaper and quicker than the manufacturers themselves due to our streamlined fabrication process.

Options are available including, but not limited to:

Coded welding to ASME Section IX and ISO9606-1#

NDT and hydrostatic testing

Complete documentation packages and full material traceability

Custom painting (for arduous offshore environments

Instrument Bridles

An instrument bridle allows you to connect two or more instrumentation technologies from one set of flanges. We can fabricate custom bridles to suit different applications or provide a combination of standard products from some of our partners.

Bridal combinations have included differing technologies in separate chambers to allow one device to remain online whilst the other is removed for maintainance.

Alternatively, where space is at a premium multiple technologies can be mounted within one chamber. For ultimate redundancy this could include a magnetic level gauge with a guided wave radar mounted on the top and a magnetostrictive or reed relay transmitter strapped to the side.

Compare signals for high confidence levels

ATEX and SIL options available

Self contained for ease of maintenance

Suitable for interface applications

Contact us to discuss your application via our form below or call +44(0)1726 839 909.

Related Documents

The AMS Process

We can contact back within 1 working day to:

- Clarify technical information

- Submit a quotation

- Organise a digital meeting to discuss your needs, or

- Arrange for a site visit to view your application

Call now on +44 (0)1726 839 909