EVOLUTION OF TRAIN LEVEL MEASUREMENT

Traditionally level control applications/systems within various storage tanks on board trains in the UK have had to be installed in conjunction with mechanical systems that provide limited feedback to operators or drivers. Investment in the UK rail fleet has brought the opportunity to include modern systems with programmable logic controllers (PLCs) or management systems with human-machine interfaces (HMIs) starting to find their way on board trains.

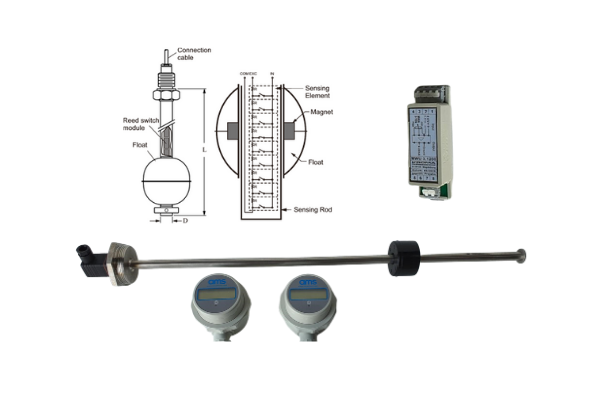

MECHANICAL LEVEL SWITCHES

Mechanical point level measurement and switching technology is reliable, robust, and fit for purpose. However, if analysis is required, using point level switches does not provide operators with accurate levels whilst the train is in motion. The result of this is limited data to provide feedback to assist with implementing efficiency changes.

Due to space restrictions onboard trains, the rail industry has not been able to fully benefit from the development of accurate level measurement devices. The progression has resulted in the introduction of a reed relay level measurement device to allow retransmission of level to remote indicators and data monitoring. However, the lack of space has meant there has still been the need for additional wiring and remote mounting of signal conditioners and transmitters in local control panels.

COMPACT ELECTRONIC LEVEL MEASUREMENT

Advances in the way instrumentation can be powered due to processing capabilities at reduced power levels, combined with the ever-continuing miniaturisation of electronics capability, has created the opportunity for rail companies to consider more modern electronic/digital technology as an alternative to the traditional methods for level measurement.

AMS-IAC have redesigned the head of one of our approved level measurement products reduce installation costs and have managed to also cut the combined sales price of the sensor and converter through the use of technology that is more widely used in other industries.

REMOTE MONITORING AND WIRELESS TRANSMISSION

These changes can allow train companies to collect data and usage statistics. In an industry where budgets are tight, electronic systems can be used to provide a better understanding of fuel use across different routes, consumption at different stages of a route, and the effect that weather conditions can have on the fuel required. An electronic system can provide a real-time level reading back to a driver and where data systems exist in a cabin this level data can be used to calculate consumption.

Successful field trials with a customer have also been completed for a new electronic display unit that can be mounted on either side of the tank to provide a physical reading of the contents level, along with a digital alarm output for low level warnings. This option allows for retransmission of the actual reading on board trains to a display in the driver’s cabin and into onboard data collection systems for analysts to monitor and provide ways to improve fuel efficiency.

For further information contact our technical team or download our Rail Tank contents measurement application note.