Storage tanks with hydrocarbons are prone to build up of water at the bottom of the tank, either from leakages in the roof, condensate and even through entrained water in the product itself.

The water can have multiple effects including misreading of stock levels, less hydrocarbon storage capacity and the potential for bacterial growth that can degrade product quality.

It is common practice to drain the water from each storage tank, this process creates the potential for the hydrocarbon to pollute the local environment and waste valuable product.

In facilities with minimal technology or where power is unavailable, the water can be drained straight from the tank and only stopped once the hydrocarbon is seen. This leads to local contamination or to contaminated water in a local bund which needs manual clearing up and disposal.

In more modern and advanced tank storage facilities, electronic level systems can be used to detect the oil and water interface level to allow for safe dewatering into a holding bund, or back into a filtration system that recovers expensive hydrocarbon that could be otherwise lost.

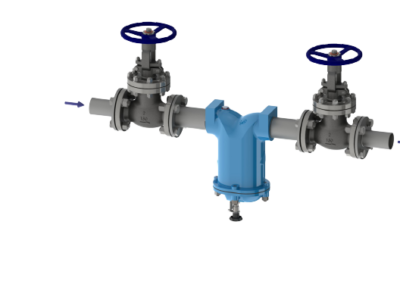

The AMS mechanical water drain valve is a float operated device that allows water to pass and then shuts off when the waters s.g. changes due to the presence of a water/hydrocarbon mix. This prevents the loss of expensive hydrocarbons and also protects the local environment from contamination.

Originally designed for use in remote airports where power supply was limited or drainage facilities didn’t exist, the valve has since been used in a number of applications including:

- as a mechanical backup device in case of failure to electronic systems

- to minimise the use of the advanced separation systems to recover fuel

- to ensure the drain lines of the separation systems don’t contain contaminated water

- a range of marine water discharge systems, including ballast emptying, where there is a potential for hydrocarbon or bilge contamination