Home > Density Sensitive Valves

For more information call +44 (0)1726 839 909 or

complete the contact form below and we will contact you

Density Sensitive Valves – Gravity Fed

A density control device with an internal float that prevents fluid flowing through when the density of the fluid changes. Sensitive up to a 1% change it can be used in a range of fluid applications to ensure fluid quality.

Designed for use in discharge lines to rivers, onboard ships which discharge water overboard, drain lines of bulk fuel storage tanks and in a range of separator applications.

Mechanical in operation and requiring no power, this simple technology that is easy to maintain can be fitted as the main prevention technology, or as backup to existing electronic systems.

-

- Saves valuable product

- Prevents pollution

- Low system cost

- Simple operation

- Easy to maintain

- Robust and built to last

For more information contact us by email below or call +44(0)1726 839 909.

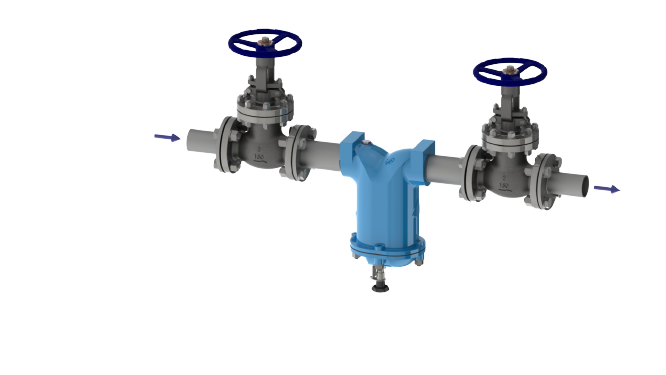

Density Sensitive Valves – Pumped System

Designed for use as a fuel grade monitor using our servo valve bodies, this float operated thornton pilot automatically shuts off when the wrong grade of fuel is detected to prevent delivery of low grade fuel or fuel into the wrong tank.

Suitable for use with any fluids, the valve and pilot combination monitors the fluid going into the valve and uses floats in the pilot to create a pressure, automatically shutting off the valve if the wrong fluid density is detected.

Installed applications include airport fuel delivery to storage tanks, fuel delivery at fuel storage terminals and mixed product storage facilities.

-

- Simple and robust

- Mechanically, float operated

- Self-contained, no power needed

- Isolates flow when wrong density detected

- Sensitive up to 1% change in density

For more information contact us by email below or call +44(0)1726 839 909.

Related Documents

The AMS Process

We can contact back within 1 working day to:

- Clarify technical information

- Submit a quotation

- Organise a digital meeting to discuss your needs, or

- Arrange for a site visit to view your application

Call now on +44 (0)1726 839 909