Home > Instrument Valves and Manifolds

For more information call +44 (0)1726 839 909 or

complete the contact form below and we will contact you

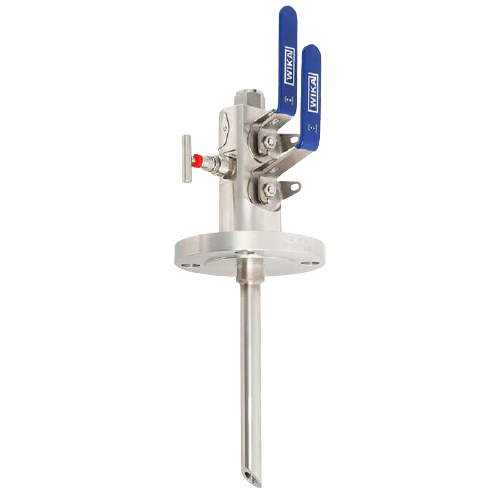

Ball Valves

A simple design with a 4:1 safety factor, for liquid and gas applications they are recommended due to the easy cleaning of the straight through internal bore. Tested to BS6755/ISO5208 leakage rate A.

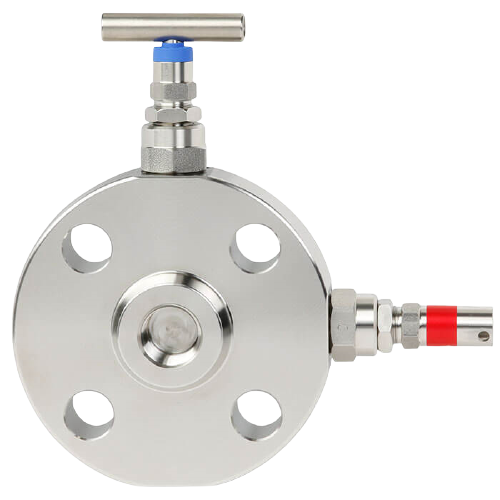

Needle Valves

Needle valves can be closed to safely remove instruments when servicing or replacing. The multiport valve has two additional connections to use as a vent or to connect multiple instruments.

Manifolds

2, 3 and 5 valve manifolds with shut off, pressure compensating, purge and vent valves for pressure and differential pressure instruments with enhanced safety due to the blow-out proof bonnet design.

Monoblock Valves

Providing increased safety for gaseous and liquid aggressive applications with metal enclosed seats and double valve body seal. Suitable for sampling systems, control panels

Related Documents

The AMS Process

We can contact back within 1 working day to:

- Clarify technical information

- Submit a quotation

- Organise a digital meeting to discuss your needs, or

- Arrange for a site visit to view your application

Call now on +44 (0)1726 839 909