Home > Pressure Measurement

For more information call +44 (0)1726 839 909 or

complete the contact form below and we will contact you

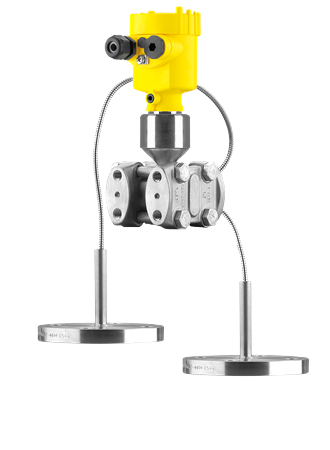

Pressure Transmitters

In addition to keeping the pressure of a process safe and under control, transmitters can be used for level, volume, density and flow measurements in gas, liquid or vapour applications.

Pressure Switches

A simple device used to open or close a mechanical or electrical switch when a high or low preset pressure has been reached. A low cost way to ensure pressure critical applications remain in control.

Pressure Gauges

Available from stock and manufactured to order, our pressure gauges provide local indication and peace of mind to operators when working around pressurised equipment and plant.

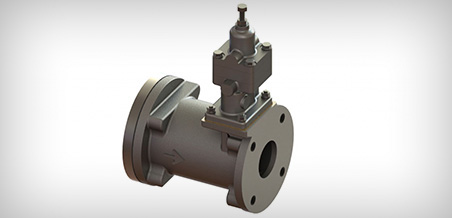

Regulating Valves

Need to maintain a constant pressure in your process, or ensure pressure spikes don’t effect your system operation or accuracy, see our range of mechanical pressure regulating valves.

Related Documents

The AMS Process

We can contact back within 1 working day to:

- Clarify technical information

- Submit a quotation

- Organise a digital meeting to discuss your needs, or

- Arrange for a site visit to view your application

Call now on +44 (0)1726 839 909