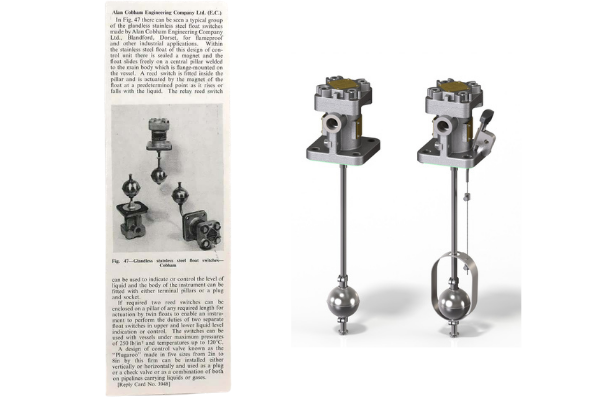

Magnetic Float Switch Article from Alan Cobham in 1963

Recently found, this article from 1963 in an engineering magazine shows details of the Alan Cobham Engineering Company Ltd float switches. It is a promotion for the company product when the manufacturing was completed in Blandford, Dorset. A picture of the original stainless steel flameproof head is shown, this is used for applications in explosion proof environments.

Float Switches Manufactured in the UK for 60 years

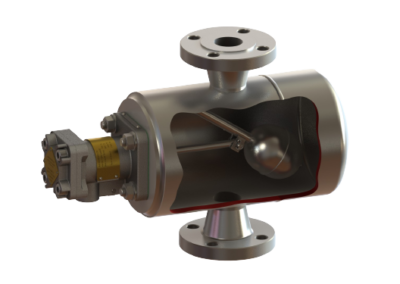

Pictured alongside the article is a version of the float switch that AMS Instrumentation and Control still manufacture. Moreover, we are using the same casting design and maintain the tradition of supply from British foundries at our Cornwall premises. This means that the products manufactured 60 years ago can still be directly replaced today. This gives customers the knowledge they can safely purchase whilst minimising any down time.

Reed switch operation

The 1963 article describes the float switch working principle, stating:

“Within the stainless steel float of this design of control unit there is sealed a magnet and the float slides freely on a central pillar welded to the main body which is flange mounted on the vessel. A reed switch is fitted inside the pillar and is actuated by the magnet of the float at a predetermined point as it rises or falls with the liquid. The relay switch can be used to indicate or control the level of liquid and the body of the instrument can be fitted with wither terminal pillars or a plug and socket.

Dual level float switch

Further down the article goes on to state:

If required two reed switches can be enclosed on a pillar of any required length for actuation by twin floats to enable an instrument to perform the duties of two separate float switches in upper and lower liquid level indication or control.”

Two reed switches create a dual level float switch to allow switching at two different levels. Due to the advancements of reed switch sizes, this area of the specification has improved over time. As a result, AMS can now manufacture level switches with up to five switch points.

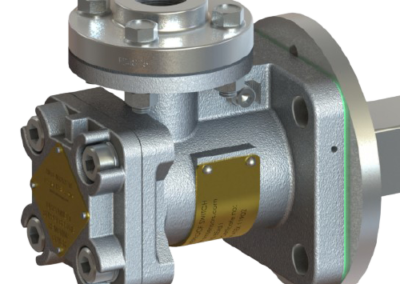

Additional explosion proof options

AMS purchased the Alan Cobham Engineering range of level and flow control products from Meggitt Refuelling Products in 2008. Since then we have added to the range of ATEX approved connection heads. This allows us to fit any flange or screwed fitting to the stem and replace other manufacturers products. For instance, we can fit to a Mobrey A flange, TAV engineering square flange and standard ANSI flanges.

For more information visit our float switches page, download our float switch specification overview brochure or contact us.