Home > Flyte Valves and Dry Break Couplings

For more information call +44 (0)1726 839 909 or

complete the contact form below and we will contact you

Our Mechanical Flyte Valves and Dry Break Couplings

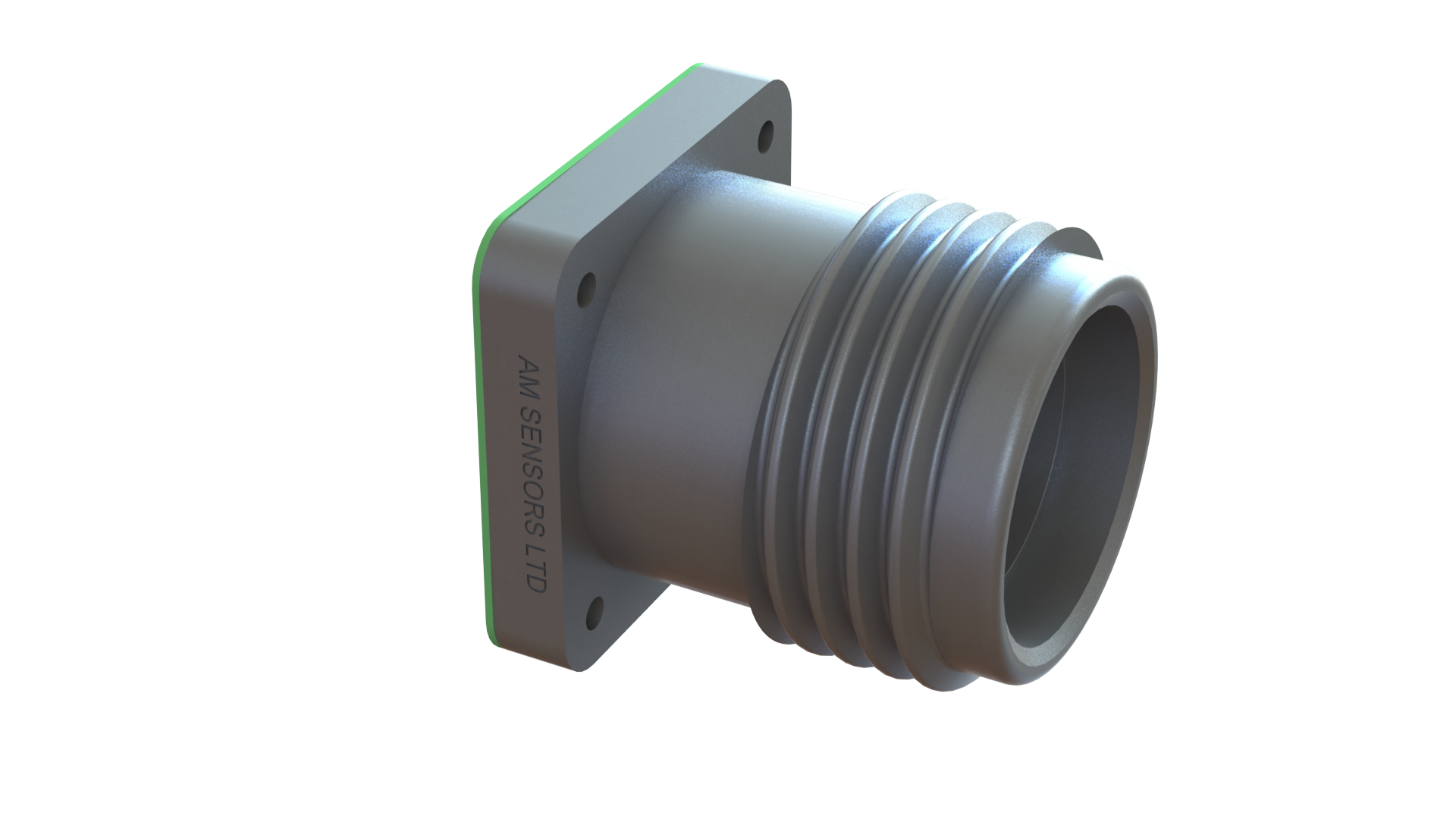

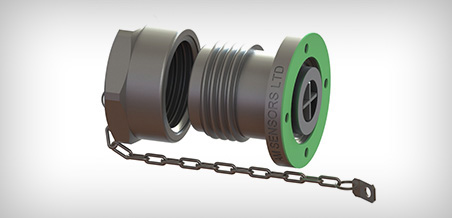

Dry Break Coupling

Designed to fit either directly to our filling valves, or to a flange on a tank or pipe, the coupling provides a dry break to prevent leakage from the filling hose when disconnecting from a storage tank.

Different flange connections allow replacement of historic brass couplings, with improved reliability, significant weight reductions and better value.

The flexibility of the design allows us to supply with alternative threaded connections to suit hose couplings for a range of applications, with additional mounting options also available to suit any existing flange connections.

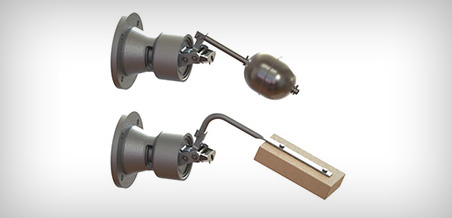

Filling Valves

Also known as the Flyte valve, the AMS vessel mounted filling control valves are a range of mechanical, float operated servo valves designed to limit the amount of liquid fed into a tank to a specific level.

Designed to allow easy self maintenance and increase the product lifespan, AMS have provided spares and factory refurbishment plans for valves that have been in service for over 20 years.

The flexible design includes adjustable arm height and length to shut off at different points, arms shaped to allow fitting to the top, side or bottom of a vessel, non return valves and pneumatic operation of remote valves.

- UK rail industry approved

- Low ownership cost, self maintenance

- Directly replaces old rail brass half couplings

- Flexible options for wide range of filling applications

- Simple operation

- Factory refurbishment plans available

Related Documents

The AMS Process

We can contact back within 1 working day to:

- Clarify technical information

- Submit a quotation

- Organise a digital meeting to discuss your needs, or

- Arrange for a site visit to view your application

Call now on +44 (0)1726 839 909